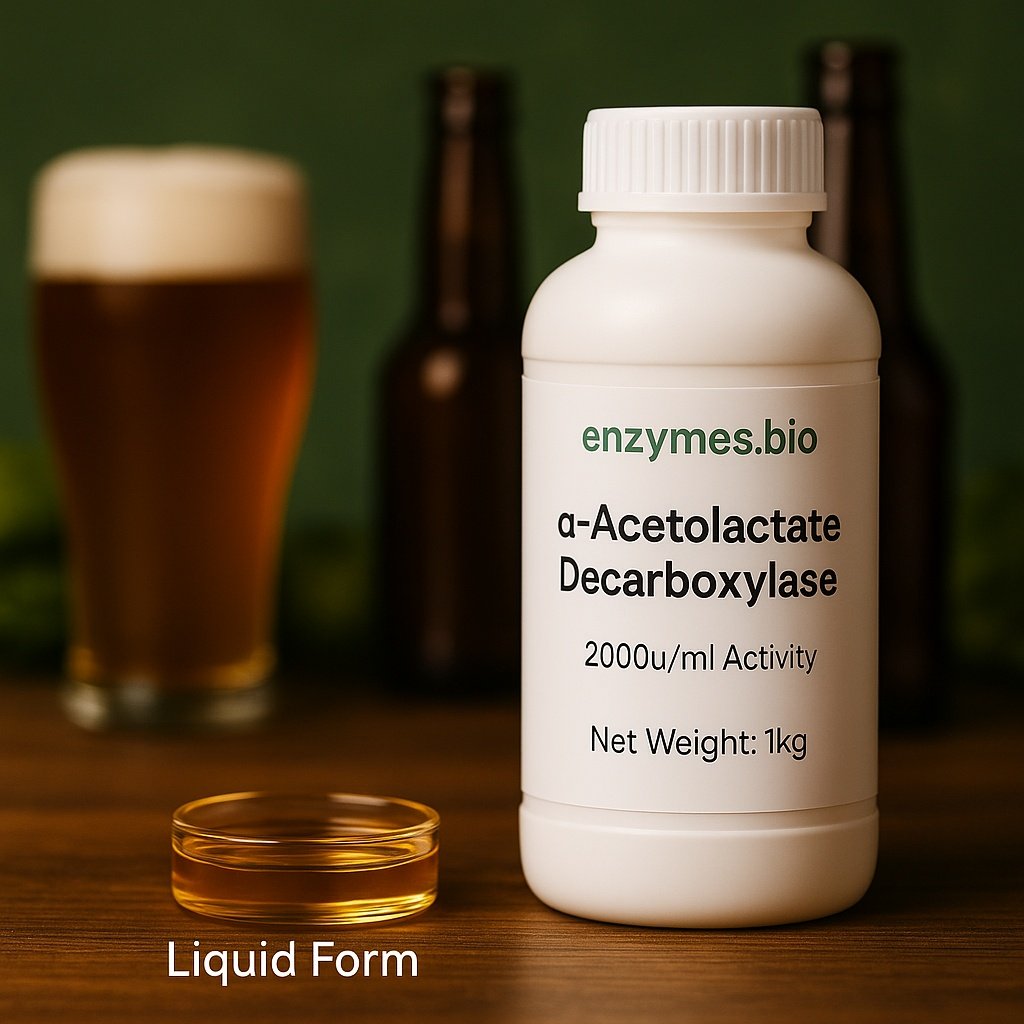

Food Grade α-Acetolactate Decarboxylase (ALDC) – 2000 U/mL Enzyme Activity

α-Acetolactate Decarboxylase (ALDC) is a highly specialized enzyme widely used in the food and beverage fermentation industry. It catalyzes the rapid decarboxylation of α-acetolactate into acetoin, effectively preventing the formation of diacetyl – a compound known for producing undesirable buttery or off-flavors in beer and other fermented products. The use of ALDC results in a cleaner, fresher, and more balanced flavor profile, while significantly shortening the maturation time of beverages.

Mechanism of Action

During fermentation, yeast produces α-acetolactate as an intermediate compound in the biosynthesis of branched-chain amino acids such as valine and leucine. Without enzymatic intervention, α-acetolactate can slowly oxidize to diacetyl, which later reduces to acetoin and 2,3-butanediol. This natural oxidation process is slow and can leave residual diacetyl, affecting flavor quality.

By adding ALDC, the enzyme catalyzes a direct decarboxylation reaction that converts α-acetolactate into acetoin, completely bypassing the oxidative step. This reaction increases the conversion rate by up to ten times faster compared with natural diacetyl reduction. The result is a dramatic decrease in diacetyl concentration, smoother flavor development, and faster conditioning of the beverage. Brewers benefit from reduced tank time, increased throughput, and improved flavor consistency batch after batch.

Key Benefits

- Reduces or eliminates diacetyl-related buttery off-flavors.

- Shortens maturation and fermentation time.

- Improves yeast productivity and process efficiency.

- Enhances flavor stability and freshness of finished beverages.

- Applicable to a wide range of food and beverage processing systems.

Recommended Applications

- Beer and craft beer production

- Cider and fruit wine fermentation

- Alcoholic beverages and flavored malt drinks

- General food flavor optimization and fermentation processes

권장 복용량

Use at a rate of 5–500 g per ton of product, depending on the specific formulation, fermentation conditions, and desired diacetyl reduction level. Preliminary small-scale testing is recommended to determine the optimal dosage for each application.

Typical Operating Conditions

- 온도 범위: 4 °C – 70 °C

- pH 범위: 3.0 – 7.5

Product Specifications

- 모습: Light yellow liquid

- 효소 활동: 2000 U/mL

- 포장: 1kg/가방

- 유통기한: 9 months under cool and dry conditions

Storage and Handling

Store in a cool, dry environment away from direct sunlight. Avoid prolonged exposure to high temperatures or humidity. Once opened, seal tightly after each use to maintain enzyme stability and activity.

Technical Insights

The enzymatic reaction pathway involves the transformation of α-acetolactate into acetoin through a fast decarboxylation process. Without ALDC, this conversion depends on slow oxidation that forms diacetyl before reduction to acetoin and 2,3-butanediol. By introducing ALDC into the fermentation system, the oxidative step is bypassed, producing acetoin directly and efficiently. This not only minimizes diacetyl accumulation but also improves the sensory characteristics of the final product.

Thanks to its high activity and wide operational range, ALDC is compatible with most brewing and food fermentation systems. It can be combined with other enzymes or processing aids to achieve synergistic effects on flavor control and fermentation speed.

결론

Food Grade α-Acetolactate Decarboxylase (ALDC) is an advanced biocatalyst that enhances fermentation performance, reduces production time, and delivers superior taste and consistency in beer and other beverages. Its robust activity and reliability make it a valuable ingredient for food processors seeking higher quality and efficiency in modern fermentation processes.