Adhesive-Contaminant Control Enzyme (Papermaking Enzyme, Industrial Grade)

This adhesive-contaminant control enzyme is designed for recycled-fiber pulping and papermaking systems to reduce stickies-related deposition during wastepaper pulping and to improve paper machine operating efficiency. It helps minimize the accumulation and interference of adhesive contaminants (stickies) formed in recycled furnish, supporting cleaner systems, more stable runnability, and better paper quality.

Key value in production:

it reduces stickies deposition during recycled-fiber pulping and improves paper machine operating efficiency. It is widely used in recycled-fiber stock preparation and board/paper production lines where stickies control is critical.

Core Benefits

- Reduce stickies deposition during wastepaper pulping (lower stickies accumulation in the system).

- Improve paper machine operating efficiency (more stable running and fewer stickies-related interruptions).

- Lower stickies-related operational obstacles, reducing breaks and re-reeling issues caused by adhesive contaminants.

- Reduce paper defects such as spots and pinholes associated with stickies contamination.

- Lower cleaning intensity for wires and felts, helping extend service life.

- Improve overall efficiency and reduce total production cost through fewer deposits and smoother operation.

Application Areas

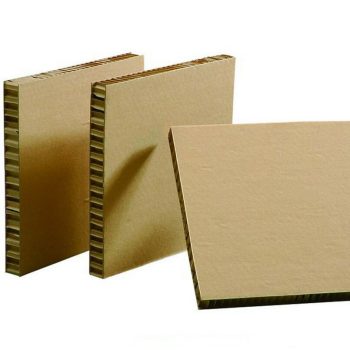

Mainly applied in recycled-fiber pulping and papermaking, including: corrugating medium and linerboard stock preparation and related recycled-board/paper processes.

Typical recycled furnishes include: OCC, MOW, OMG, ONP and other recycled paper sources.

Applicable scope:

suitable for recycled-fiber production processes using secondary fiber as the main raw material, such as corrugating medium, linerboard and related grades.

Product Information

- Recommended dosage: 100–200 g per ton (oven-dry pulp).

- Operating temperature: 35–65 °C.

- Operating pH: 6.0–10.0.

- Reaction time: 45–90 minutes.

- Addition point: after the pulper tower stage or in the stock storage chest before the paper machine approach flow / sizing-related storage chest (as applicable).

- Addition method: batch-wise or continuous dosing depending on the pulping/stock-prep process.

- Appearance: brown to dark-brown liquid (slight fermentation odor).

- Packaging: Standard packaging is 1 kg bottle (supplied in an industrial-grade plain bottle). Please note that the product image is for illustration purposes. Actual packaging may differ.

- Shelf life / storage stability:

- Up to 6 months under normal ambient conditions.

- Up to 1 year under refrigerated conditions.

- Store away from direct sunlight, keep sealed, and keep dry. Best stored at approximately 4 °C.

Mechanism

The enzyme helps control adhesive contaminants by breaking down key components commonly found in recycled-fiber stickies (such as resin acid esters, synthetic rubber, and related adhesive substances). These materials are converted into more water-soluble, low-molecular-weight compounds. At the same time, the enzyme action supports dispersion and stabilization of micro-fine particulate stickies and hydrolysis products, helping prevent re-agglomeration into larger particles. As a result, the contaminants are less likely to deposit on equipment or fibers and are more likely to be carried through the system for removal with the process flow.

Production Outcomes You Can Expect

- Reduced stickies accumulation and deposition during recycled-fiber pulping.

- Lower stickies-related downtime, breaks, and runnability disturbances.

- Cleaner wet-end conditions and improved paper/board appearance quality.

- Less frequent and less intensive cleaning for forming fabrics and felts, supporting longer lifetime.

- Improved machine efficiency and lower overall manufacturing cost.

Positioning

Industry-forward solution for stickies control in recycled-fiber papermaking systems, supporting stable production and improved efficiency.