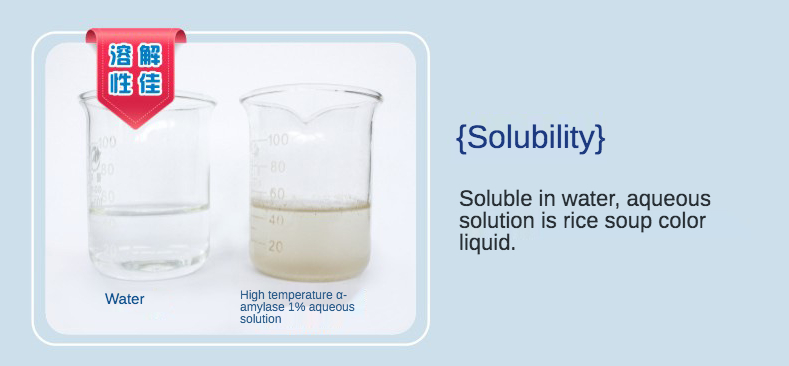

Soluble in water, the aqueous solution is rice soup colored liquid.

In the process of weaving, fibers need to be sized to increase the fastness. When dyeing, bleaching, and printing, the sizing needs to be removed. The use of amylase can rapidly change the starch sizing into dextrin, and the liquefied soluble dextrin can be washed with water.

High-temperature α-amylase is refined by fermentation and extraction of Bacillus licheniformis. It can rapidly hydrolyze the α-1.4 glucosidic bond in the starch molecule at a higher temperature and arbitrarily cut it into short-chain dextrins of different lengths and a small amount of oligosaccharides, thus causing the viscosity of starch to drop rapidly. The liquefaction time is extended, and a small amount of glucose and maltose will also be produced. This product has good high-temperature resistance.

Product Characteristics:

1. Temperature range: The optimum action temperature is above 90℃, liquefaction is rapid at 95-97℃, and it still keeps considerable vitality at 100℃, and the instant temperature can reach 105-110℃ when it is liquefied by spraying.

2. PH range: The effective pH range is 5.5-8.0, the optimum pH range is 6.0-6.5.

3. The effect of calcium ion on enzyme activity: This product does not require high Ca2, starch hydrolysis is recommended to add 50-70ppm.

Mechanism:

This product is a hydrolytic enzyme, which can randomly hydrolyze starch, glycogen, and its hydrolysate internal α-1.4 glucosidic bond at higher temperatures, producing soluble dextrin and a small amount of oligosaccharide, making the viscosity of gelatinous starch solution drop rapidly, and excessive hydrolysis can produce a small amount of glucose and maltose.

Activity Definition:

The amount of enzyme required to liquefy 1 mg of soluble starch in 1 minute at 70°C and pH 6.0 is 1 unit of enzyme activity. The unit is u/g.

Product Specification:

100,000u/g.

Product Properties:

Light yellow or white powder.

Application Areas:

This product is widely used in starch sugar (glucose, caramel, dextrin, fructose, oligosaccharide), alcohol, beer, monosodium glutamate, food brewing, organic acid, textile, printing and dyeing, paper making, and other fermentation industries.

1. Powder processing: High-temperature amylase can adapt to higher reaction temperatures, suitable for pH weak acid conditions, mainly used in the glycation of starch, through the decomposition of the glycosidic bond in starch, the production of soluble dextrin.

2. Brewing industry: High-temperature resistant amylase is used to replace malt for beer auxiliary liquefaction. Compared with the traditional malt dextrin method, enzymatic dextrin is easy to produce and operate, with a good liquefaction effect and reasonable wort composition, so that the physical and chemical indexes and taste of beer can be improved.

3. Textile industry:

Examples of use conditions in beer brewing:

- In the process of beer brewing, after the auxiliary materials and water are mixed evenly, add about 0.3 liters (20,000u/m) of this enzyme for each ton of auxiliary materials, which can be added at one time and rapidly warmed up at 95-97℃ and kept warm for about 30 minutes.

- In alcohol production, add about 0.3 liters (20,000u/ml) of this product with each ton of raw material, pH 6.5-7.0, stir well and then send it into the cooking pot or continuous cooking heater by pump, the temperature can be controlled at 100±5℃, the time is 100 minutes, after cooling and saccharification.

- When applied in MSG and starch sugar industry, adjust the pH to 6.0-6.5 and add about 0.6 liter (20,000u/ml) of this enzyme per ton of raw material. If interval liquefaction is adopted, the temperature can be rapidly increased to 100±5℃ in the liquefaction tank and kept at 95-100℃ for more than 30 minutes; if jet liquefaction is adopted, the jet temperature can be around 105℃ and kept at 95℃ for 60-120 minutes.

Storage:

The enzyme preparation will lose its vitality gradually with time in different degrees under different storage temperatures. It is recommended to be stored in a cool and dry environment, and should be stored under low temperature and protected from light.

If stored for too long or under unfavorable storage conditions, such as high temperature and humidity, it is necessary to increase the addition amount appropriately at the time of use.

Safety:

High-temperature resistant α-amylase is a pure natural enzyme preparation; it is protein, consuming food with enzyme preparation is like consuming food with protein, it is beneficial and harmless to the human body. For some sensitive people, if they directly ingest highly concentrated enzyme powder or droplets, it may cause allergy; too long contact may irritate skin, eyes, and mucous membrane tissue.

It is recommended to wear protective gears such as a mask and eye protection during the operation, and the remaining or spilled enzyme powder should be disposed of in time. For a large amount of spilled enzyme powder, it should be gently swept back to the container, while a small amount should be vacuumed away or cleaned up by wetting with water.

Medium-temperature amylase is a kind of bioactive material, which is easily inhibited and damaged by heavy metal ions (Fe3+, Cu2+, Hg+, Pb+, etc.) and oxidant, so contact with it should be avoided in the process of storage or use.