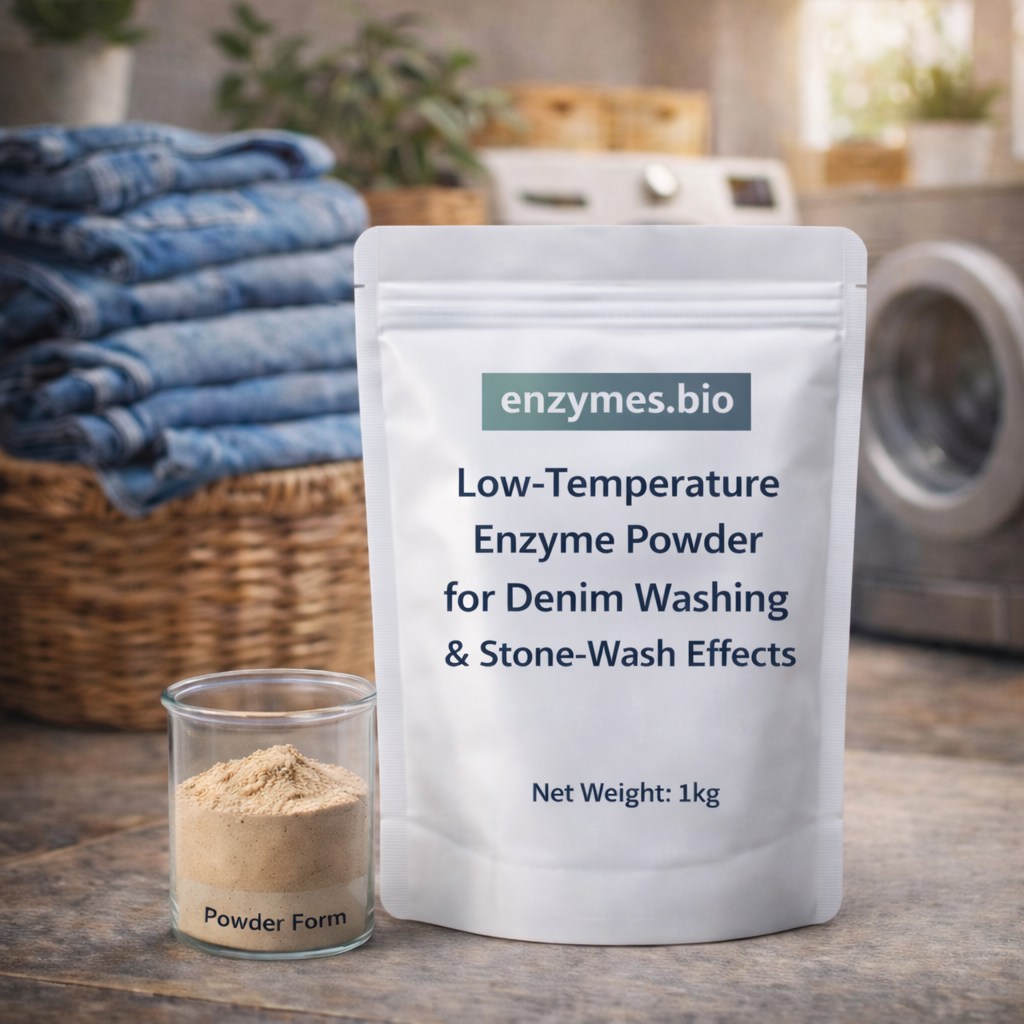

Low-Temperature Enzyme Powder for Denim Washing & Stone-Wash Effects

This low-temperature enzyme powder is a professional-grade cellulase solution developed specifically for modern denim washing processes that require fast abrasion development, controlled color contrast, and reliable fabric protection. It is designed to perform efficiently under mild processing conditions, helping manufacturers achieve classic stone-wash and enzyme-wash aesthetics while maintaining garment strength and consistency.

By selectively acting on the surface fibers of cotton-based fabrics, the enzyme gently removes loose microfibrils and surface fuzz. This controlled bio-polishing action reveals natural denim texture, enhances visual depth, and produces a clean, even fading effect without excessive damage. The result is a softer hand feel, clearer grain definition, and a refined vintage appearance.

Key Performance Advantages

- Low-Temperature Efficiency – Active and stable within a processing temperature range of 25–45°C, reducing energy consumption and minimizing thermal stress on fabrics.

- Fast Flowering / Abrasion Development – Rapid enzymatic response shortens washing cycles while delivering clear stone-wash and enzyme-wash effects.

- Stable Backing & Fabric Protection – Controlled enzymatic action helps prevent over-processing, excessive strength loss, and uneven abrasion.

- Enhanced Hand Feel – Improves smoothness and softness, delivering a clean, comfortable touch suitable for daily-wear denim.

- Consistent Visual Results – Produces uniform fading and well-defined contrast, ideal for vintage, casual, and washed-down denim styles.

Processing Conditions

- Recommended Temperature: 25–45°C

- Applicable pH Range: 5.0–8.0

- Typical Treatment Time: 15–60 minutes

The enzyme operates effectively across a broad pH window, providing flexibility for different denim wash recipes and compatibility with commonly used auxiliaries. Proper control of time, temperature, and pH allows manufacturers to fine-tune abrasion intensity and surface appearance.

Dosage Guidelines

- Recommended Usage: 300–500 g per batch (equivalent to approximately 120–200 pairs of adult denim jeans)

- General Reference: Under normal conditions, adding 200 grams of enzyme per batch can reduce the use of one bag of pumice stones.

Actual dosage and application methods should be optimized through pilot trials, as fabric composition, garment construction, and process parameters may vary.

Applicable Fabrics & Uses

- Denim garments and denim fabrics

- Cotton, cotton-blend, linen, and lyocell-based textiles

- Stone-wash, enzyme-wash, and bio-polishing processes

- Processes aiming to replace or reduce the use of pumice stones

Compared with traditional chemical washing techniques, enzymatic washing offers a more controlled and sustainable approach. The enzyme is derived from natural fermentation sources and supports cleaner processing while delivering high-quality aesthetic and tactile results.

Storage & Handling

- Store in a sealed container in a cool, dry environment

- Recommended storage temperature: 2–25°C

- Avoid direct sunlight and moisture exposure to maintain activity

Safety Information

This product is supplied in powder form. In sensitive individuals, enzyme dust may cause mild irritation or allergic reactions. Avoid unnecessary skin contact and inhalation. If contact occurs, rinse thoroughly with clean water. Use appropriate protective equipment during handling.

Supplied by enzymes.bio in 1 kg per bag format, sealed food-grade aluminum foil bag. Please note that the product image is for illustration purposes. Actual packaging may differ. Suitable for professional denim washing, garment finishing, and industrial textile applications.