Product Description

Medium Temperature Amylase is an endo-starch hydrolase extracted by deep fermentation culture of selected Bacillus subtilis, followed by microfiltration, ultrafiltration, and vacuum freeze-drying technology. It is widely used in the industries of starch sugar, alcohol, brewing, monosodium glutamate, glucose, organic acid, and antimicrobial agent.

Medium temperature amylase can hydrolyze soluble starch, straight chain starch, glycogen, etc. in a medium temperature (60-85℃) environment with high efficiency. By randomly cutting the a-1,4 glucosidic bond in the sugar chain, starch and glycogen can be decomposed into dextrin and oligosaccharide monosaccharide with different chain lengths, which can rapidly reduce the viscosity of the solution.

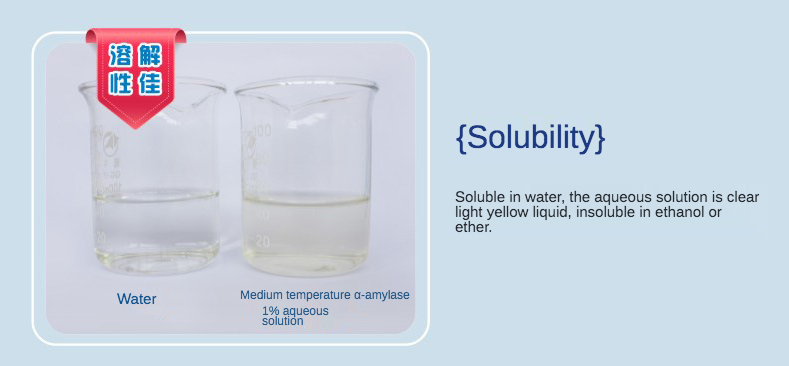

It is easily soluble in water, and the aqueous solution is clarified light yellow liquid, insoluble in ethanol or ether.

Main components: medium temperature α-amylase, glucose

Product specification: 10,000-20,000 U/g (can be customized)

Product properties: light brown powder

Storage: room temperature dry and protected from light

Shelf life: 12 months

Applications

- Fixed powder processing: Medium temperature amylase can be applied in the production of sugar with starch as raw material, such as caramel, maltodextrin, maltose, etc.

- Brewing and fermentation industry: Medium temperature amylase can be used in wine brewing, soy sauce, vinegar brewing, and other industries to break down starch into monosaccharides available to yeast, shorten the brewing cycle, and improve filtration speed.

- Baking industry: Medium-temperature amylase can be used in flour improvement, promoting yeast reproduction, increasing fermentation speed, and reducing sugar content in bread, cake, cookie, and other baking processing.

- Grain processing: Medium-temperature amylase can be applied to pretreatment of cereal raw materials to improve solubility and increase nutritional value.

- Health supplement: Amylase can be used in the processing of digestion-promoting drugs, dietary supplements, and nutritional fortification of plant ingredients.

Introduction

Medium temperature α-amylase is a type of enzyme that performs the same function as high temperature α-amylase, but at a lower temperature. The heat of high temperature α-amylase has been shown to be very effective at breaking down starch into sugar.

What is Starch?

Starch is the combination of starch (polysaccharides) and proteins. It is known as the most abundant carbohydrate in nature, more than four times more abundant than water. Starch is used in a wide variety of foods, beverages, pharmaceuticals, and industrial products.

Starch itself is available in several forms:

- Starch granules are formed in the plant cell membrane (cell wall) during photosynthesis. Most starch synthesized by plants is stored inside this wall or cell wall until it can be released to the outside environment.

- Starches also exist as granular or powdery forms, as well as hygroscopic forms that are formed when moisture is present around plant cells.

Starch undergoes partial hydrolysis during its passage through the digestive tract. This process involves enzymes called amylases (also called starcheside hydrolases), which break down starch into smaller molecular units called amylopectin subunits.

The needs of the wine brewing industry

Medium temperature α-amylase is a salt produced by yeasts that is used as a medium-temperature enzyme to break down starch into monosaccharides. Its application in wine brewing, soy sauce, vinegar brewing, and other industries can greatly reduce fermentation time and produce higher quality wines with better filtration capacity.

The emergence of medium temperature amylase

A medium temperature α-amylase has been developed at the University of Tokyo. It is used to break down starch and other polysaccharides into monosaccharides that are available to yeast, shorten the brewing cycle, while effectively reducing viscosity and improving filtration speed.

Medium temperature amylase for beer brewing

When a brewery is looking for a way to increase the efficiency of their fermentation process without increasing the temperature, one of the options could be using medium temperature α-amylase. This is an enzyme from Bacillus subtilis, which works at a slightly higher temperature than medium temperature amylase. It also can be used in more complex beers made with adjuncts and other ingredients. The reason it’s useful for brewing beer is that it breaks down starch into sugar, allowing the hops to extract more bitterness from the beer.

Medium temperature amylase for wine brewing

A medium temperature α-amylase is an enzyme used in winemaking to break down starch into monosaccharides, a process that has been called the most effective way to shorten the brewing cycle. α-amylase is an enzyme that breaks down starch into monosaccharides. Commercial uses include winemaking, soy sauce, vinegar brewing, and other industries. In winemaking, α-amylase is beneficial for breaking down starch into monosaccharides and facilitating filtration of pulp for better fermentation.

Medium temperature amylase for vinegar brewing

Medium temperature α-amylase, or α-Amylase, can be used in the production of wine and other alcoholic beverages, such as soy sauce, vinegar brewing, and other industries to break down starch into monosaccharides available to yeast, shorten the brewing cycle. The main reason for using it is that it is a very efficient way of converting starch into sugar without the use of any heat. Currently, there are no commercial products that are produced in this form; however, a number of companies have experimented with producing food products using this form of medium temperature amylase (α-Amylase). In its simplest form, medium temperature α-Amylase consists of a mixture with α-amylose (a type of starch), which can be prepared from plants or animal products; a small amount of medium temperature enzyme (enzyme A), and a small amount of water. This can be stored in an airtight bag at room temperature for up to 6 months. With proper storage conditions and proper selection of plant materials, medium temperature α-Amylase appears to function well in both winemaking and vinegar brewing.

Future

If you’re a maker, you probably know about this product. But did you know that it can be used in other industries to break down starch into monosaccharides? This is especially useful in making wine, soy sauce, vinegar, and other types of foods. It is also handy for breaking down corn starch and the like into the monosaccharides glucose and fructose (glucose + fructose = sucrose). This is because the alternative to using high-temperature α-amylase is working with enzymes such as amylases that are produced by yeasts and bacteria for many years now. In its simplest form, it consists of using a medium temperature α-amylase to break down starch into sugar. There are different types of medium temperature α-amylase; however, the most commonly found one is called L-α-Amylase (α-Amylase). This type of medium temperature α-amylase is much more common than the others. The downside to using this type of medium temperature amylase in food manufacturing is that it has a very short shelf life. Another drawback to using this type of medium temperature amylase specifically in food manufacturing is that they require baking or other forms of heating up beforehand. And while they are great when used in conjunction with high temperatures α-amylase, they don’t have as much effect on saccharide levels as if used at lower temperatures (e.g. 50°C vs 70°C). If you have an interest or knowledge about mechanisms behind fermentation and use fermentation techniques at home or work, then getting your hands on some medium temperature α-amylases may just be the next thing on your mind!

Using α-amylase in the baking industry

Introduction

Medium-temperature α-amylase is a product that can be used to improve the flavor and texture of flour. It can be used as a medium-temperature amylase in bread, cake, cookie, and other baking processing. It has been widely used in bread, cake, cookie, and other baking processing since its introduction. For example, it can be used to improve the taste of flour or enhance the texture of flour by using it as a medium temperature amylase in bread, cake, cookie, and other baking processing.

The medium-temperature amylase

In this study, we investigate the effects of medium-temperature α-amylase on bread flour. The effect of medium-temperature α-amylase on flour composition was analyzed by determining protein and glucose contents, pH and color, which were measured by the alkaline titrimetric method. Medium-temperature α-amylase significantly lowered the protein and glucose contents when compared to those of the control group. Medium-temperature α-amylase also lowered the pH value when compared to that of the control group; however, it had no significant effect on color. The main components for bread flour were protein (42.59%), carbohydrate (50.43%), and water (5.47%), respectively; medium-temperature α-amylase significantly increased all three components towards a decrease in the gluten content. Our results indicate that medium-temperature α-amylase can be used to promote starch decomposition in flour by lowering protein and glucose levels and improving the pH value of flour.

The mechanism of starch decomposition

We know that amylase is a powerful enzyme, which is mainly responsible for the starch digestion in our body. However, it is poorly understood what exactly amylase does and how it works. To answer this question, we will do an in-depth study of the mechanism of starch decomposition with the help of α-amylase medium temperature.

Application in grain milling

The grain milling industry is a fast-growing one in the United States, and among those who are making a living off it, there are many people who have been trying to figure out how to improve the grain milling process to make it more efficient and reduce costs. One of the most common ways of doing so is through modifying the medium temperature α-amylase, which is one of the most widely used additives in grain mills. It’s been just over 20 years since high-speed and energy-saving grain mills were first introduced on a large scale, but these mills have yet to reach the same level of popularity as they once did. Although this has led to an increase in sales, which has allowed companies like Elanco and Archer Daniels Midland (ADM) to create their own brands and sell their products directly to consumers, many would argue that there is still room for improvement. For instance, as ADM’s president, Paul Smith states: “There are two main problems plaguing our business: high costs for raw materials and ineffective technology for producing quality flour.” Something that may come as a surprise is that grains aren’t all about sugar – there are quite a few different kinds of flour that you can use for baking or other processes, including wholemeal flour (made from wheat), white flour (made from wheat), mocha flour (made from soybeans), and brown rice flour (also known as brown rice). If you want your product to be sold by people who have no idea what they are looking at (and they don’t necessarily have to be buyers either), then it would be best if you got rid of all those pesky confusing words like wholemeal or mocha or whatever else clog up your message. The only thing that matters about them is your message! Also: keep in mind! There are plenty of people out there who will not buy any product unless it comes with some kind of gluten-free tag attached (you know just how many!). They care about how you labeled your product because they don’t want their children eating something potentially harmful. As such, you should always think carefully about labeling your product before launching into production if you can help it.

Conclusion

In the last few weeks, a great deal of attention has been given to the “uncoupling” of food and climate. As a result, I have been asked many questions concerning the use of medium-temperature α-amylase in food processing, particularly in bread and pancake production. I will try to answer some of these questions here. While it is true that wheat flour is able to withstand temperature extremes better than white flour, traditional culinary applications require that it is not heated to such high temperatures as are found in industrial applications (for example, baking in bakery ovens). It must be heated at low temperatures so that it can coagulate or convert starch into glucose (which is then immediately used by yeast and other microorganisms for fermentation). Therefore, there are two main problems facing manufacturers who want to use medium-temperature α-amylase for food processing: (1) the presence of high moisture content and (2) high temperature. The low temperature means that α-amylase cannot effectively convert starch into glucose; as a result, it will not decompose starch and will also not produce glucose. On the other hand, due to moisture content, the higher temperature reduces enzyme action rate. Additionally, even if there were no moisture content problems with wheat flour, its high cooking temperature would still be a problem due to the heat used during baking. Nevertheless, because most bread manufacturing plants do use heat during baking or frying while producing or reusing wheat flour for production purposes (such as bakeries), we must solve both problems without having too much concern about quality control issues related to moisture content issue. And if one only needs high-quality flour for baking purposes — e.g., farina — then increasing its resistance against temperature extremes may be less important than if they are using it for extrusion/extrusion mixing or deep-frying process. As an example of how this works out with our product: when we started developing our product for commercialization purposes which required more than 1 kg / bag output from large plant equipment (elevator), our prototype was developed based on my earlier research report. As expected from our prototype design from the theoretical analysis and simulation study, we mainly focused on designing materials that provided good resistance against all types of extreme temperatures like near freezing (-20°C/-4°C), boiling (+18°C/+12°C), +20°C/+30°C.

Amylase for Health Supplement Industry

Introduction

Medium temperature α-amylase (MT α-Amylase) is a highly digestible and effective enzyme type which can be used in the processing of digestion promoting drugs to ease the digestive burden. The powder does not contain any harmful substances or sugars, it is beneficial for people who want to control their weight and are suffering from diabetes and obesity.

Amylase introduction

Medium temperature α-amylase is a product which is used in the processing of digesting drugs. It can also be applied to dietary supplements and nutrition. This article explains how to use medium temperature α-amylase in the processing of digestive enzymes.

Digestion of carbohydrates

Digestion is a complex process involving five major enzymes, which break down carbohydrates into simpler compounds for absorption in the small intestine (the stomach). The digestion of carbohydrates is facilitated by an enzyme called α-amylase. α-Amylase is a digestive enzyme that speeds up digestion by breaking down food items into their components, including glucose and other simple sugars such as fructose and lactose. For example, glucose can be absorbed into the