Feed Grade Thermostable and Acid-Resistant Phytase Enzyme for Animal Additive

Introduction

Phytase ultra (Phytase Premier I) [EC 3.1.3.26] is produced from Aspergillus niger through advanced fermentation and extraction technology.

It is thermostable and good tolerant to pepsin and trypsin. It can break down the undigestible phytic acid (phytate) and release digestible phosphorus, calcium, and other nutrients. As an animal feed additive used in poultry and swine, it can enhance the nutritive value by liberation of inorganic phosphate from phytic acid (myo-inositol hexakisphosphate), thereby reducing phosphorus pollution to the environment.

Definition of Unit

1 unit of phytase equals to the amount of enzyme, which liberates 1 μmol of inorganic phosphorus in 1 min, from 5.0mmol/L sodium phytase at 37℃ and pH5.0.

Specifications

| Enzyme Activity | 5,000u/g; 10,000u/g |

| Appearance | White or Yellowish powder |

Products can be customized according to customer’s demand.

Recommended Dosage

| Used for Complete Feed | Growth Stage | Dosage: (g/MT) | |

| ≥5000 u/g | ≥10,000 u/g | ||

| Swine | 20-35 kg | 150 | 75 |

| More than 35 kg | 120 | 60 | |

| Poultry | Whole period | 200 | 100 |

| Layer | Brooding period | 200 | 100 |

| Laying hens | 60 | 30 | |

| Laying duck | 80 | 40 |

Enzymes Properties

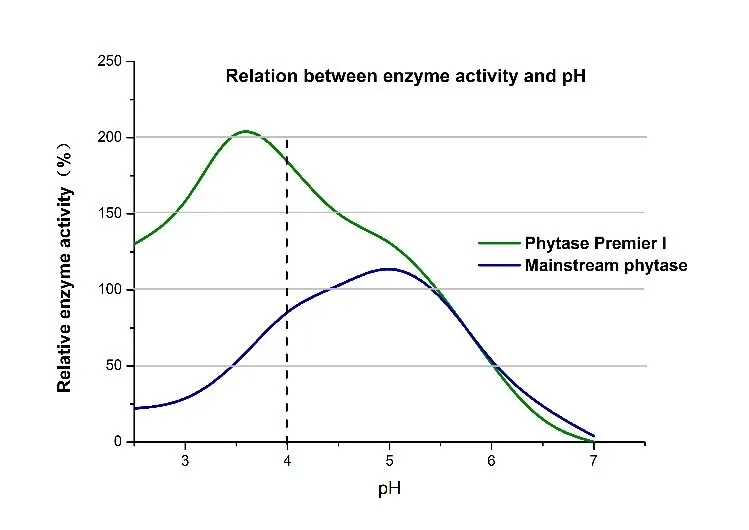

1. Enzyme properties at different pH conditions

The optimum pH of ENZYMES.BIO Phytase Premier I was 3.5 and the pH range was from 2.5 to 5.5. Compared to the current mainstream phytase in the international market, ENZYMES.BIO phytase Premier I showed higher activity between pH 2.5 to 5.5, which was more suitable for the digestion of phytic acid in the animal gastrointestinal tract.

Fig. 1. Relation between phytase activity and pH

Note: The mainstream phytase means the current mainstream phytase in the international market.

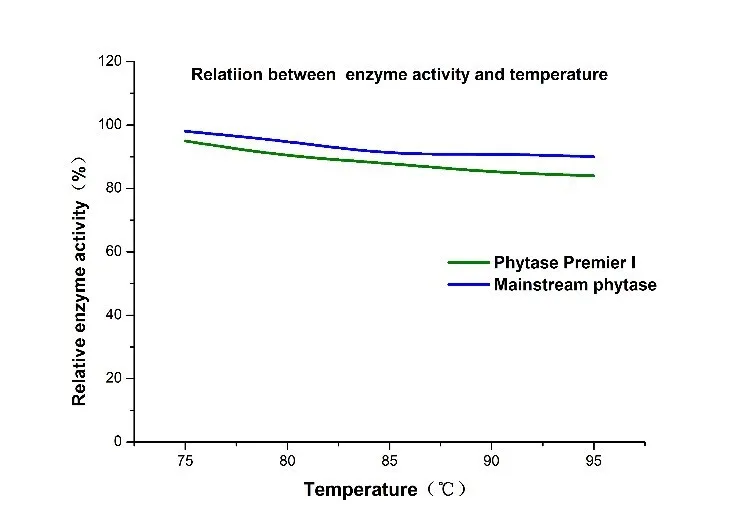

2. Temperature stability

The activity of Phytase Premier I could maintain 80% or more, which results showed the phytase had very good heat resistance.

(water bath for 3min under 75℃~95℃) Fig. 2. Relation between phytase activity and temperature

3. Stability under the feed pelleting process

An experiment was conducted in a feed factory in Shandong province. The phytase was fixed with the swine’s feed, conditioned for 90s at 85℃, 0.4MPa and pelleted for 10s in a Modulator (AG, CH-9240, Bühler Co., Wuxi China), testing the thermostability during the feed pelleting process.

| Source | Phytase Premier I | Mainstream phytase |

| Retention Rate | 84% | 88% |

Phytase Premier I maintained high activity under the feed pelleting process.

4. Tolerance to Endogenous Protease

Table 2 Resistance to Pepsin and Trypsin

| Condition | Resistance to Pepsin | Resistance to Trypsin | ||

| Buffer | Buffer + Pepsin | Buffer | Buffer + Trypsin | |

| pH | 2.5 | 2.5 | 6.5 | 6.5 |

| Temperature | 40℃ | 40℃ | 40℃ | 40℃ |

| Time | 1.5h | 1.5h | 2h | 2h |

| Protease Concentration | __ | 1mg/ml | __ | 2.5mg/ml |

Compared to the current mainstream phytase in the international market, ENZYMES.BIO phytase Premier I has better resistance to endogenous protease.

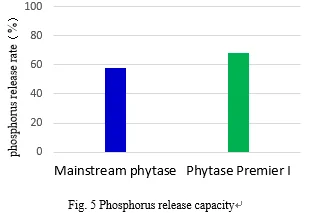

5. Phosphorus Release Capacity

The phytase was mixed with soybean meal, incubated at 40℃ for 4h at pH 3.0, then transferred to pH 6.5, 40℃ for 4h. Phosphorus release was determined as below.

Results showed Phytase Premier I had a much higher phosphorus release capacity than the mainstream phytase.

Functions & Benefits

• Effectively hydrolyze phytic acid in the plant materials, increase the phosphorus utilization rate of feed raw material.

• Reduce the dosage of inorganic phosphorus and save the cost of animal feed.

• Break phytanate frame, release nutrients, like: starch, protein, mineral elements, increase the utilization rate.

• Improve the absorption of phosphorus and reduce environmental pollution.

Advantages

• Produced through advanced liquid fermentation and extraction technology.

• Good resistance to endogenous protease and gastric acid.

• Thermostable, wide pH range, catalyzing effectively in the animal gastrointestinal tract.

• Even granular, appropriate grain size, blend equally.

• Highly concentrated and cost-saving.

Package

1 kg / bag.

Storage

The shelf life is 12 months under 20℃.

Damp and insolation should be avoided. Store it in a cool, dry, and ventilated place.