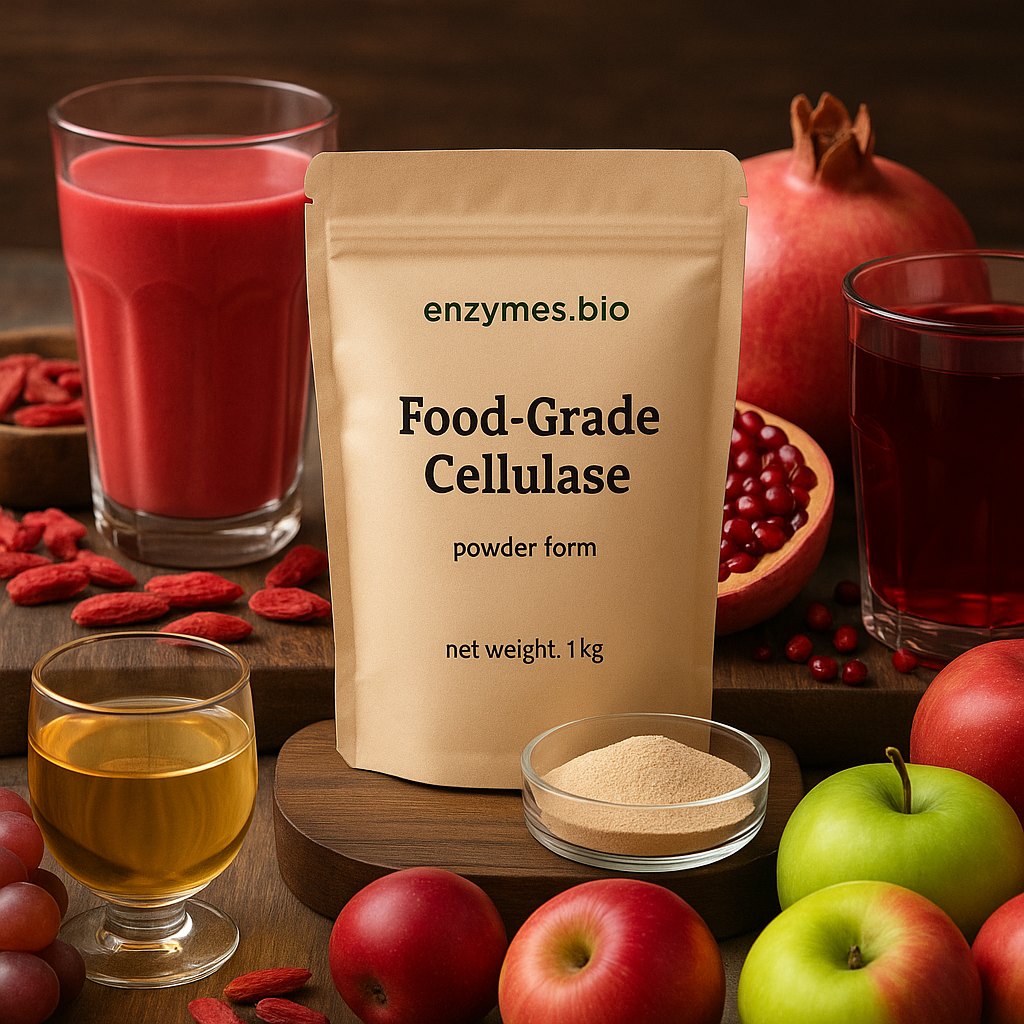

Enzim selulase gred makanan untuk ekstraksi botani

Enzim selulase gred makanan premium kami dirumus khas untuk menyokong pengekstrakan berkesan tinggi sebatian bioaktif daripada bahan mentah botani. Ia digunakan secara meluas dalam pemprosesan ekstrak herba, ekstrak buah dan sayur, pekatan tumbuhan, dan penjernihan jus. Dengan memecahkan selulosa dan hemiselulosa dalam dinding sel tumbuhan, enzim ini meningkatkan hasil pengekstrakan dengan ketara, memperbaiki ketelusan, dan memendekkan masa pemprosesan.

Mengapa Memilih Cellulase Ini?

- Memaksimumkan kecekapan pengekstrakan dengan merosakkan struktur dinding sel tumbuhan

- Melepaskan lebih banyak sebatian aktif seperti polifenol, flavonoid, polisakarida, dan pigmen

- Meningkatkan kejelasan ekstrak dan prestasi penapisan

- Mengurangkan kelikatan ekstrak tumbuhan untuk memudahkan pemprosesan susulan

- Sesuai untuk pelbagai jenis bahan botani termasuk akar, batang, daun, buah, beri, dan kulit

- Enzim berkanji gred makanan dengan kelarutan yang sangat baik

Aplikasi Tipikal

Enzim selulase ini banyak digunakan dalam:

- Ekstraksi herba (akar, batang, daun, bunga, buah, kulit)

- Pengilangan bahan berasaskan tumbuhan

- Pengekstrakan dan penjernihan jus buah

- Ekstraksi beri dan buah merah (beri goji, blueberry, delima, dan lain-lain)

- Meningkatkan hasil pengekstrakan pigmen semula jadi

Dos yang Disyorkan

| Permohonan | Dos yang Disyorkan | Nota |

|---|---|---|

| Penjernihan jus anggur | ~0.05% | Berdasarkan berat bahan mentah |

| Pengekstrakan beri dan buah merah | ~0.05% | Meningkatkan warna dan pelepasan sebatian aktif |

| Ekstraksi beri goji | 0.3% | Meningkatkan penapisan dan kejelasan |

| Ekstraksi botani umum | 0.1–1% | Laraskan berdasarkan jenis bahan tanaman dan proses. |

Arahan Penggunaan

Untuk prestasi terbaik, ikuti garis panduan pemprosesan yang disyorkan:

Rendam bahan tumbuhan dalam air pada suhu 40–50°C selama kira-kira 30 minit mengikut nisbah bahan kepada cecair yang diperlukan. Larutkan enzim selulase dalam air pada suhu kira-kira 40°C selama 5–10 minit untuk mengaktifkannya. Setelah larutan ekstraksi mencapai suhu dan tahap pH yang diingini, tambahkan larutan enzim perlahan-lahan sambil kacau perlahan. Lakukan hidrolisis enzimatik pada suhu malar selama kira-kira 1–3 jam (bergantung pada bahan tumbuhan tertentu). Setelah rawatan enzimatik selesai, teruskan dengan proses pengekstrakan mengikut keperluan.

Spesifikasi Teknikal

- Penampilan: Serbuk kuning muda hingga beige

- Aktiviti: 3500 U/g (kompleks selulase gred makanan)

- Suhu Optimum: 55–65°C

- pH optimum: 4.0–6.0

- Jangka hayat: 12 bulan apabila disimpan dalam keadaan tertutup dan kering

- Pembungkusan: Disalurkan dalam 1 kg/beg, beg foil aluminium gred makanan yang disegel. Sila ambil perhatian bahawa imej produk adalah untuk tujuan ilustrasi. Pembungkusan sebenar mungkin berbeza.

Bagaimana Ia Berfungsi

Dinding sel tumbuhan terutamanya terdiri daripada selulosa, hemiselulosa, lignin, dan pektin. Enzim selulase ini memecahkan struktur yang kaya dengan selulosa, membolehkan pelarut menembusi dengan lebih berkesan dan melepaskan komponen tumbuhan yang berharga. Hasilnya ialah hasil yang lebih tinggi, ekstraksi warna yang lebih baik, pelepasan rasa yang dipertingkatkan, dan penapisan yang lebih lancar.

Contoh Aliran Kerja Aplikasi (Ekstraksi Botani)

Proses ekstraksi botani dengan bantuan enzim biasanya bermula dengan bahan tumbuhan mentah, yang pertama kali dihancurkan dan kemudian dikenakan ekstraksi air. Semasa peringkat ekstraksi akuatik, selulase boleh ditambah untuk mempromosikan penguraian dinding sel tumbuhan dan meningkatkan pelepasan sebatian intraselular. Selepas ekstraksi air, enzim tambahan seperti pektinase, amilase, atau protease mungkin disertakan bergantung pada keperluan proses, sekali gus meningkatkan larutan bahan aktif dan memperbaiki ketelusan.

Ekstrak yang terhasil kemudian ditapis untuk menyingkirkan komponen yang tidak larut, menghasilkan cecair yang lebih jernih yang seterusnya dibawa ke langkah pemekatan, di mana komponen aktif diperkayakan. Ekstrak pekat biasanya menjalani pemendakan alkohol, satu langkah yang digunakan untuk memisahkan kekotoran atau memendakkan sebatian aktif tertentu. Supernatan atau endapan yang diperoleh daripada pemendakan alkohol kemudian dipekatkan semula untuk mencapai ekstrak dengan ketulenan yang lebih tinggi.

Pemprosesan seterusnya bergantung pada bentuk produk akhir yang diingini. Jika matlamatnya adalah untuk menghasilkan serbuk ekstrak kering, ekstrak pekat boleh diproses dan dikeringkan terus untuk mendapatkan serbuk pepejal. Bagi produk serbuk yang lebih halus, teknologi pengeringan seperti pengeringan vakum, pengeringan semburan atau pengeringan kabus boleh digunakan untuk mencapai kebolehsaluran yang lebih baik, kestabilan yang dipertingkatkan dan ciri zarah yang konsisten. Secara keseluruhan, penggunaan beberapa enzim secara gabungan meningkatkan kecekapan ekstraksi, ketulenan dan kualiti produk sepanjang keseluruhan aliran kerja ekstraksi botani.

- Pembersihan dan penggelekan bahan mentah

- Pengekstrakan air

- Penambahan enzim dan hidrolisis

- Penapisan dan penjernihan

- Konsentrasi

- Pengeringan (pengeringan semburan, pengeringan vakum, atau pengeringan beku)

Enzim selulase ini adalah alat serbaguna dan berkesan untuk meningkatkan kualiti, kecekapan, dan hasil pengekstrakan serta pemprosesan tumbuhan.

Ia sesuai untuk pengeluaran ekstrak herba tradisional dan pembuatan bahan fungsi moden.