Food Grade Alpha Amylase In Bread Baking Enzyme Powder Industry SBE-03FA

Introduction

SBE – 03FA is a fungal amylase used in the flour and baking industry. It is fermented by Aspergillus oryzae, which can break down starch particles into short-chain molecules to achieve starch dextrinization and saccharification. This product contains no other enzyme activities. It is produced according to the food-grade enzyme standards issued by FDA, FAO, WHO, and UECFA, which are in accordance with the FCC. SBE – 03FA can be used to improve flour quality and create tailored flour. It can also be directly used in powder form to enhance the processing quality of steamed buns and bread.

Definition Of Unit

1 unit of Fungal α-Amylase equals the amount of enzyme that hydrolyzes soluble starch to produce 10mg of reducing sugar (glucose) at 40℃ and pH 5.0 in 30 minutes.

Characteristics

| Declared Activity | 100,000 u/g |

| Production Organism | Aspergillus oryzae |

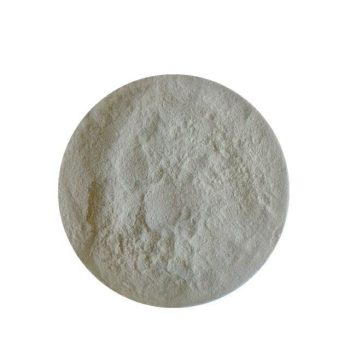

| Physical Form | Powder |

| Color | Yellowish. Color can vary from batch to batch. Color intensity is not an indication of enzyme activity. |

| Odour | Normal microbial fermentation odour. |

Specifications

| ITEMS | Lower Limit | Upper Limit |

| Enzyme Activity | 100,000 u/g | |

| Lead | 5 mg/kg | |

| Arsenic | 3 mg/kg | |

| Total Viable Count | 50,000 CFU/g | |

| Coliform Bacteria | 30 CFU/g | |

| Escherichia coli | 10 CFU/g 3 MPN/g | |

| Salmonella | Not Detected/25g |

Functions & Benefits

• Speed up fermentation and shorten the time.

• Improve the organizational structure of steamed buns and bread, increasing the internal softness and volume.

• Improve crust color, enhancing the overall quality of bread.

Recommended Dosage

For the baking industry: The recommended dosage is 2-4g per ton of flour. The optimal dosage depends on the quality of the flour and the processing parameters and should be determined by baking or steaming tests. It is advisable to start the test with the smallest quantity.

Package

Packaging specification: 1 kg / bag.

Storage

Best Before: When stored as recommended, the product is best used within 12 months from the date of delivery.

Shelf Life: 12 months at 25℃, with activity remaining ≥90%. Increase dosage after the shelf life.

Storage Conditions: This product should be stored in a cool and dry place in a sealed container, avoiding exposure to sunlight, high temperatures, and moisture. The product has been formulated for optimal stability. Extended storage or adverse conditions such as higher temperatures or humidity may require a higher dosage.

Safety

Enzyme preparations are proteins that may induce sensitization and cause allergic reactions in sensitized individuals. Prolonged contact may cause minor irritation to the skin, eyes, or nasal mucosa, so direct contact with the human body should be avoided. If irritation or allergic responses develop on the skin or eyes, consult a doctor.