Product Description

Overview

Neutral protease is an inscribed protease, refined and extracted using microfiltration, ultrafiltration, and vacuum freeze-drying technology after submerged fermentation culture of Bacillus subtilis 1398. With a molecular weight, it is ideal for protein hydrolytic treatment in various industries such as food, medicine, feed, cosmetics, nutrition, and health care products.

Characteristics

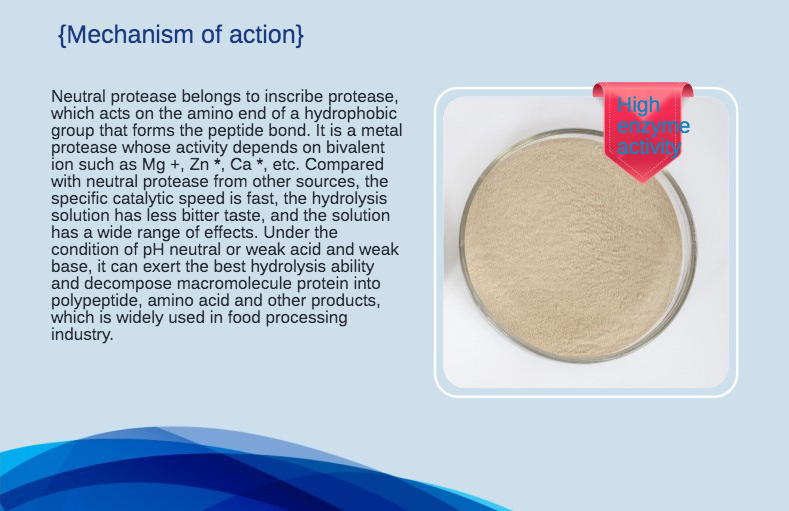

Neutral protease belongs to inscribed protease, acting on the amino end of a hydrophobic group forming the peptide bond. It is a metal protease whose activity depends on bivalent ions such as Mg+, Zn*, Ca*, etc. Compared to neutral protease from other sources, it has a specific catalytic speed, less bitter taste in hydrolysis solutions, and a wide range of effects. It works best under neutral or weak acid and weak base pH conditions, breaking down macromolecule proteins into polypeptides, amino acids, and other products, widely used in the food processing industry.

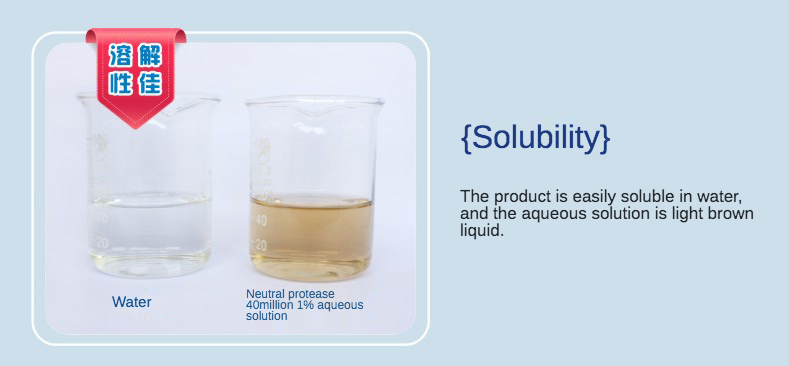

The product is easily soluble in water, resulting in a light brown liquid aqueous solution.

Product Information

- Product Name: Neutral Protease

- Ingredients: Neutral protease, glucose product

- Specifications: 10 million – 60 million U/g (customizable)

- Product Characteristics: Ivory to light brown powder

- Preservation Method: Normal temperature drying and dark preservation

- Shelf Life: 12 months

Applications

Neutral protease is used in the baking industry to make cookies, reducing mixing and fermentation times. Through enzymatic reactions, the protein in the dough is hydrolyzed, weakening dough strength while improving plasticity and extensibility. This results in clear and beautiful printing patterns, enhanced gloss, uniform structure, and a crisp taste.

It is a non-toxic and non-side-effect protein suitable for hydrolyzing animal and vegetable proteins with high AN%, high hydrolysis degree, and good taste, producing advanced condiments and food nutrition enhancers.

In the beer industry, neutral protease achieves good clarification effects and can be combined with other enzyme systems to form beer complex enzymes for better clarification and bitter taste removal.