Ipari lúgos xilanáz a cellulóz- és papírfeldolgozáshoz

Ipari lúgos xilanáz egy ipari minőségű enzimkészítmény, amelyet a modern cellulóz- és papírgyártási folyamatokhoz terveztek. Szelektíven hidrolizálja a lignocellulóz rostokban lévő xilánt és a kapcsolódó hemicellulóz frakciókat, segítve a cellulóz szerkezetének optimalizálását és a folyamat teljesítményének javítását a cellulóz gerinc bontása nélkül.

Lúgos xilanáz genetikailag optimalizált mikrobatörzs felhasználásával mélyfermentációval állítják elő, és magas 1,4-β-D-xilanáz-aktivitást tartalmaz. Ez a termék hatékonyan hat a növényi rostokban jelen lévő xilánra és arabinoxilánra, hasítva a xilán gerinc β-1,4 glikozidos kötéseit. Ennek eredményeként a xilán xilózzá bomlik, fellazítva a szálszerkezetet, javítva az áteresztőképességet és elősegítve a belső szálkomponensek felszabadulását.

Ez a lúgos xilanáz olyan anyagok enzimes kezelésére használható, mint a fapép, fa, bambusz, növényi nyersanyagok, dohánylevelek és állati takarmány.

A papírgyártó rendszerekben a hemicellulóz komponensek, mint például a xilán, akadályokat képezhetnek a szálak felületén és a szálhálózaton belül, korlátozva az áteresztőképességet és csökkentve a későbbi műveletek hatékonyságát. Ez a lúgos xilanáz e célzott komponensek lebontásával támogatja a jobb tömegátadást, a cellulóz nagyobb reakciókészségét a feldolgozás során és a stabilabb gépüzemet.

Elsődleges felhasználás

Ezt a terméket elsősorban a következőkben használják cellulóz- és papíripar mint feldolgozási segédeszköz a működési hatékonyság és a papírminőség javítása érdekében.

Legfontosabb előnyök a papírgyártásban

- A fényerő javítása

Támogatja a nagyobb cellulózfényességet a xilánnal kapcsolatos akadályok csökkentésével, ami segíthet a folyamat hatékonyságának növelésében a cellulózkezelési és mosási fázisok során. - Viszkozitáscsökkentés

Javítja a cellulóziszap folyási tulajdonságait és csökkenti a viszkozitást, segít stabilizálni a szivattyúzást, a rostálást és az áramlásszabályozást a gyártósorokon. - Gyorsabb szűrés és vízelvezetés

Javítja a cellulóz áteresztőképességét és a vízleadás teljesítményét, javítja a szűrési sebességet és a víztelenítés hatékonyságát, hogy támogassa a zökkenőmentesebb, nagyobb teljesítményű műveleteket. - Kompatibilis a semleges-lúgos rendszerekkel

Úgy tervezték, hogy megbízhatóan működjön az ipari papírgyártási folyamatokban általánosan előforduló körülmények között, különösen semleges és lúgos környezetben. - Szelektív hatás a szálak szilárdságának megőrzése érdekében

Célzottan a hemicellulóz-frakciókat célozza, miközben megőrzi a cellulózlánc integritását, támogatva a végső papírtermék konzisztens fizikai tulajdonságait.

Alkalmazási területek

- Papíripari rostanyag előkezelés és folyamatoptimalizálás a papírgyártásban

- Kémiai cellulóz, mechanikai cellulóz és vegyes cellulóz rendszerek

- Nyomópapír, írópapír, csomagolópapír és kapcsolódó papírtermékek

- Mosási, szűrési és víztelenítési hatékonyságnövelő szakaszok

Ajánlott folyamatparaméterek

| Ajánlott adagolás | 10 - 2000 g/tonna száraz rost |

|---|---|

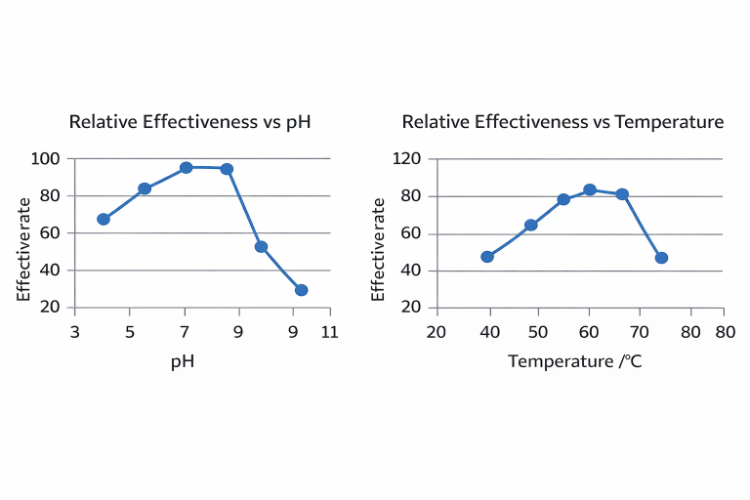

| Alkalmazható pH-tartomány | 6.0 - 9.0 |

| Alkalmazható hőmérséklet | 35 - 65 °C |

| Reakcióidő | 45-90 perc |

| Addíciós módszer | Batch vagy folyamatos adagolás a folyamat tervezése szerint |

A legjobb eredmény elérése érdekében optimalizálja az adagolást és az érintkezési időt a pép típusa és a berendezés konfigurációja alapján,

és célzott teljesítményeredmények, mint például fényerő, viszkozitáscsökkentés és szűrés vagy

vízelvezetési sebesség.

Hogyan kell használni

Ez az enzim hozzáadható tételesen vagy folyamatosan a folyamat elrendezésétől függően. Az egyenletes teljesítmény támogatása érdekében tartsa a működési feltételeket az ajánlott pH- és hőmérsékleti tartományokon belül, és hagyjon elegendő tartózkodási időt a kívánt reakcióhatás eléréséhez.

Csomagolás

Standard csomagolás: (ipari minőségű sima palackban szállítva). Kérjük, vegye figyelembe, hogy a termékkép illusztrációs célokat szolgál. A tényleges csomagolás ettől eltérhet.

Tárolás és kezelés

Hűvös, száraz, közvetlen napfénytől védett helyen tárolja. Használaton kívül tartsa lezártan a csomagolást. Az enzimaktivitás megőrzése érdekében kerülje a magas hőmérsékletnek vagy nedvességnek való tartós kitettséget.

Összefoglaló

Az ipari lúgos xilanáz praktikus enzimatikus megközelítést kínál a cellulóz- és papírgyártók számára, akik jobb fényerőre, csökkentett iszapviszkozitásra, valamint gyorsabb szűrési és vízelvezetési teljesítményre törekszenek. Zökkenőmentesen integrálódik a papírgyártási munkafolyamatokba, és támogatja a hatékony, stabil ipari működést.