Enzymes are proteins that can catalyze a chemical reaction. Enzymes thus play a major role in the metabolism of organisms. The word enzyme originally comes from the Latin word “fermentum” (fermentation) and was later translated into Greek as an artificial word. Enzymes are produced, on the one hand, during the production of beer during malt production. Enzymes are produced when the grain is watered and brought to germination. These enzymes are formed to break down protein and starch. With the help of the enzymes, the reserve substances of the grain turn into soluble substances and help the germ bud to grow.

Enzymes are also used in the fermentation itself. The enzyme alcohol dehydrogenase is responsible for the production of ethanol during fermentation. However, the enzyme alcohol dehydrogenase is also responsible in the human body for converting methanol into toxic formaldehyde. Methanol is found in large quantities, especially in low-grade alcohol products. The conversion of methanol to formaldehyde by the enzyme alcohol dehydrogenase can damage important proteins in the body when high doses of alcohol are consumed.

The performance of our brewing enzymes portfolio is backed by the most advanced science. Enzymes are brewing aids that offer a specific benefit to functions or processes. That benefit can be producing beer faster, simpler, more sustainably and more cost-effectively. Thus, you can have better control of the brewing process, regardless of the type of operation you perform or the raw material you use. Our brewing enzymes are extremely easy to use and can be added to your existing production processes simply and quickly.

Innovation is a core element in improving the profitability of beer products. We help our customers develop new products by introducing a variety of product portfolios. Are you looking for a way to produce gluten-free beer? Using barley/complementary parts instead of malt, or planning to brew your beer with brand new ingredients? We work with you to ensure the consistency and quality of your beer, and our goal is to bring you a quality product that is cost-effective.

There is a growing global trend for a variety of beer types and styles, such as gluten-free and flavoured beers. prevalent. It is also an excellent opportunity for brewers to increase their market share and establish a real competitive advantage. By using brewing enzymes, you can replace malt, which is an expensive brewing ingredient, and you can also combine it with unmalted barley. It is used as a new raw material to brew a high quality beer with a refreshing taste and rich foam.

Do you want to improve brewing efficiency and produce high quality beer at a low cost? Our range of brewing enzymes is ideal for you and will help you produce clear, consistent beer.

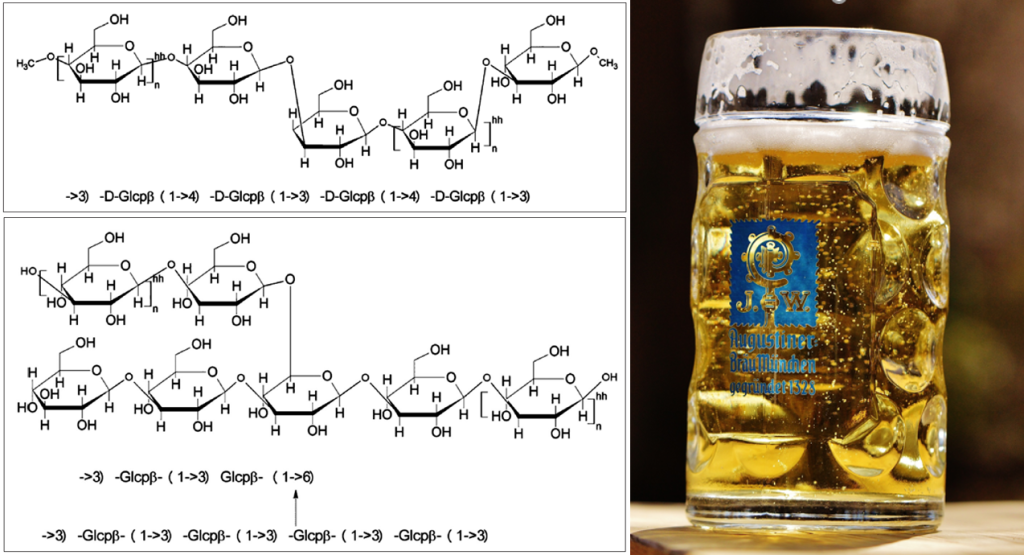

The β glucan in the beer brewing process is mainly derived from barley grains and yeast cell walls, which can cause beer turbidity, reduce beer filtration efficiency and affect the non-biological stability of beer. The addition of 1-20 ppm composite enzyme preparation SF408 to the filtrate after 30-60 minutes of filtration of the brewer’s yeast sludge can effectively degrade β glucan in beer and improve the clarity and stability of beer.