Product Description

The Alpha-galactosidase is produced by submerged fermentation of a selected microbial strain followed by purification, formulation, and drying. It is used to remove anti-nutrient factors, such as raffinose and stachyose, to solve digestion problems. The product is also capable of hydrolyzing galactomannans synergistically with mannase.

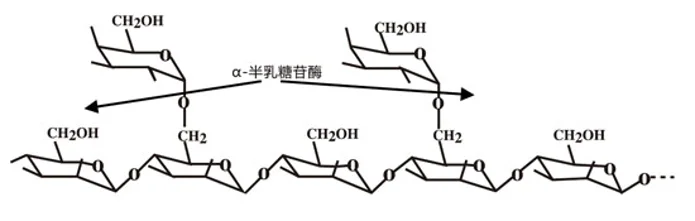

Mechanism

Alpha-galactosidase is a homodimeric glycoprotein that splits off the terminal alpha-galactosyl moieties. It is able to catalyze the hydrolysis of melibiose into galactose and glucose and therefore also called mellibiase. Since there are anti-nutritional carbohydrates, i.e., raffinose and stachyose, containing galactose residuals linked with bond in α-configuration in some feed raw materials, the use of the enzyme will remove these anti-nutrients and convert them into readily absorbable nutrients.

Product Standard

| No. | Items | Index | |

| 1 | Particle size (%<40 mesh) | ≥80 | |

| 2 | Loss on drying/(%) | ≤8.0 | |

| 3 | Lead/(mg/kg) | ≤5.0 | |

| 4 | Arsenic/(mg/kg) | ≤3.0 | |

| 5 | Total viable count/(CFU/g) | ≤50000 | |

| 6 | Coliform Bacteria/(CFU/g) | ≤30 | |

| 7 | Escherichia coli | (CFU/g) | <10 |

| (MPN/g) | ≤3.0 | ||

| 8 | Salmonella/(25g) | Not Detected |

Reaction Parameters

| Condition | Range |

| Activity Temperature | 30℃-50℃ |

| Optimum Temperature | 40℃-50℃ |

| Activity pH | 2.0-6.0 |

| Optimum pH | 4.5-5.5 |

Recommended Dosage

The recommended dosage is 0.01-1 kg/t DS. The dosage has to be optimized based on each application, the raw material specifications, product expectation, and processing parameters. It is better to begin the test with the convenient volume.

Safe Handling Precautions

Enzyme preparations are proteins that may induce sensitization and cause allergic types of symptoms in susceptible individuals. Prolonged contact may cause minor irritation for skin, eyes, or nasal mucosa. Any direct contact with the human body should be avoided. If irritation or allergic response for skin or eyes develops, please consult a doctor.