Food Grade α-Galactosidase Enzyme – Processing Aid for Raffinose and Stachyose Reduction

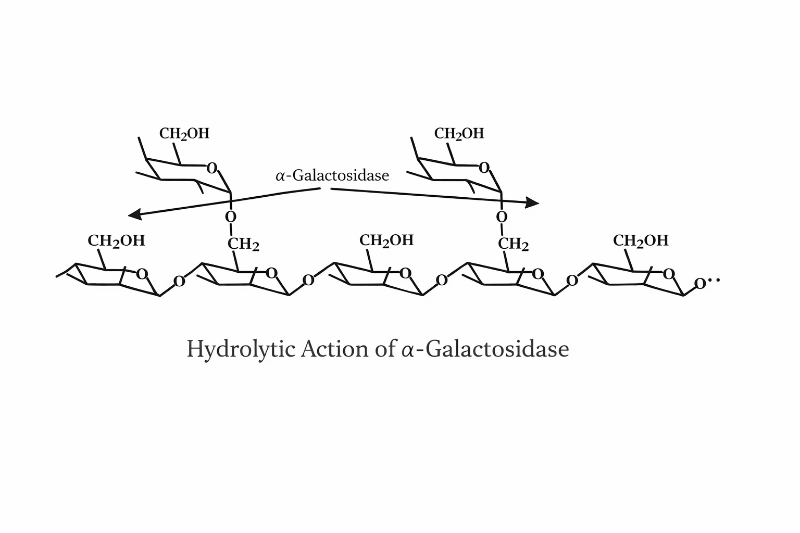

Food Grade α-Galactosidase is a specialized hydrolytic enzyme used in food processing to improve the quality, digestibility, and sensory performance of plant-based ingredients. It is designed to break down α-1,6 galactosidic bonds found in naturally occurring oligosaccharides such as raffinose and stachyose, which are commonly present in soybeans, legumes, and many plant protein systems. These oligosaccharides are widely recognized as key contributors to digestive discomfort because they are not efficiently digested in the human upper gastrointestinal tract.

During processing, α-galactosidase enzymatically hydrolyzes these indigestible sugars into smaller, more digestible saccharides, helping manufacturers create products that are gentler on digestion while also delivering a cleaner flavor and smoother mouthfeel. This makes it especially valuable for brands and manufacturers producing soy foods, plant-based beverages, fermented foods, and functional nutrition products where consumer expectations for taste, comfort, and ingredient functionality continue to rise.

Key Benefits

- Reduces raffinose and stachyose by hydrolyzing α-galactoside bonds commonly found in legumes and soy ingredients

- Improves digestive tolerance by lowering hard-to-digest oligosaccharides that may lead to bloating and discomfort

- Enhances flavor and mouthfeel by supporting cleaner plant-based profiles and smoother texture perception

- Supports better nutrient utilization by reducing oligosaccharide-related anti-nutritional effects in high-legume formulations

- Flexible processing compatibility suitable for soaking, slurry treatment, beverage formulation, and fermentation preparation steps

Recommended Processing Conditions

- Temperature range: 25℃-62℃ optimal 45℃–50℃

- pH range: 3.0~9.0 optimal 4.5-6.0

- Recommended dosage: 0.01–0.5 kg per metric ton (adjust based on substrate and process conditions)

For best results, add the enzyme during a mid-temperature processing stage where pH and temperature fall within the recommended ranges, and allow sufficient time for enzymatic hydrolysis to occur. The ideal dosage depends on multiple factors including the proportion of soy/legume ingredients, solids concentration, residence time, and the desired degree of oligosaccharide reduction. Pilot trials are recommended to determine the most efficient use level for each product and production line.

Applications

Soy and Legume Foods

- Tofu and soybean curd products

- Legume-based protein foods and snacks

- Processed soy and bean ingredients where improved tolerance is required

Plant-Based Beverages

- Soy milk, soy drink bases, and soy-derived beverage concentrates

- Plant protein beverages including soy and pea blends

- Emulsified plant-based drinks requiring improved flavor and consumer experience

Fermented Foods and Cultured Products

- Fermented soy beverages and yogurt-style plant products

- Fermented legume foods and cultured plant-based solutions

- Fermentation preparation steps where oligosaccharide reduction supports better outcomes

Functional Nutrition and Ingredient Systems

- High-protein and high-fiber powder mixes

- Meal replacement powders and nutrition blends

- Plant-based formulations targeting improved digestibility and consumer comfort

How It Works

Many plant-based raw materials naturally contain α-galactoside oligosaccharides. Because the human digestive system has limited endogenous α-galactosidase activity, these sugars often pass undigested into the colon, where they are fermented by microbiota and may generate gas. In plant-based food manufacturing, reducing these oligosaccharides during processing can significantly improve end-product tolerance and consumer satisfaction.

α-Galactosidase hydrolyzes α-1,6 galactosidic linkages, converting raffinose- and stachyose-type oligosaccharides into smaller sugars that are more digestible. This enzymatic action can improve product positioning for consumers seeking plant-based nutrition without compromising comfort. In addition, lowering oligosaccharide content often contributes to a smoother sensory profile, especially in soy beverages and legume-heavy formulations.

Product Form

- Appearance: light yellow powder

- Grade: food grade

- Activity: 10000 U/g

- Packaging: Supplied in 1 kg/bag, sealed food-grade aluminum foil bag. Please note that the product image is for illustration purposes. Actual packaging may differ.

- Shelf life: 12 months when stored sealed in a cool, dry place

Usage Notes

- Performance depends on substrate type, solids content, processing time, temperature, and pH.

- Ensure uniform dispersion for consistent activity throughout the batch.

- Compatible with multi-enzyme processing systems such as protease and amylase depending on product goals and formulation complexity.

Storage

Store sealed in a cool, dry place away from heat and moisture. Avoid prolonged exposure to high temperature or humidity. Close tightly after opening and use promptly to maintain enzyme activity.