Industrial Grade Neutral Pectinase E3100

Introduction

Neutral Pectinase E3100 is a liquid enzyme preparation specifically designed for applications in the paper industry.

It plays a vital role in breaking down pectin and pectin-derived substances present in pulp suspensions.

By targeting dissolved and colloidal substances (DCS), this enzyme helps optimize pulp treatment, reduce chemical demand,

and improve overall papermaking efficiency. Its neutral pH range and high stability make it especially suitable for

modern paper mills aiming to reduce costs while improving quality and sustainability.

Mechanism

Pectin substances and pectin-derived colloids can accumulate in pulp suspensions, increasing cationic demand and causing

interference in the papermaking process. Neutral Pectinase E3100 degrades these compounds effectively, resulting in:

- Lower DCS content and reduced cationic demand

- Less requirement for retention aids and fillers

- Improved water drainage and system cleanliness

- Enhanced fine fiber retention for higher yield

Characteristics

Form: Liquid enzyme

Activity: 3000 U/g (dilutable for lower activity requirements)

Optimal Temperature: 45°C – 65°C

Optimal pH Range: 5.0 – 8.0

Shelf Life: 6 months when stored properly

Storage: Store in a cool, dry, and ventilated place. Avoid direct sunlight and keep sealed after use.

Applications

Neutral Pectinase E3100 has been developed for use across a wide range of pulp and paper industry processes:

- Pulp Processing: Reduces dissolved and colloidal substances, improving pulp purity

- Chemical Savings: Lowers demand for cationic agents, fillers, and retention aids

- Yield Enhancement: Improves fine fiber retention, contributing to higher pulp utilization

- Debarking & Chip Processing: Facilitates handling of raw wood and chips by reducing pectin-related interference

- Beating & Refining: Improves overall efficiency of mechanical pulp treatment

Recommended Dosage

Typical dosage ranges from 5% – 20% depending on the formulation and pulp concentration.

It is recommended to add continuously in the pulp slurry. The optimal dosage should be determined by on-site trials

based on specific raw material composition and production conditions.

Specifications

Package: 1 kg / bag

Formulation: Liquid enzyme concentrate

Usage: For industrial use only

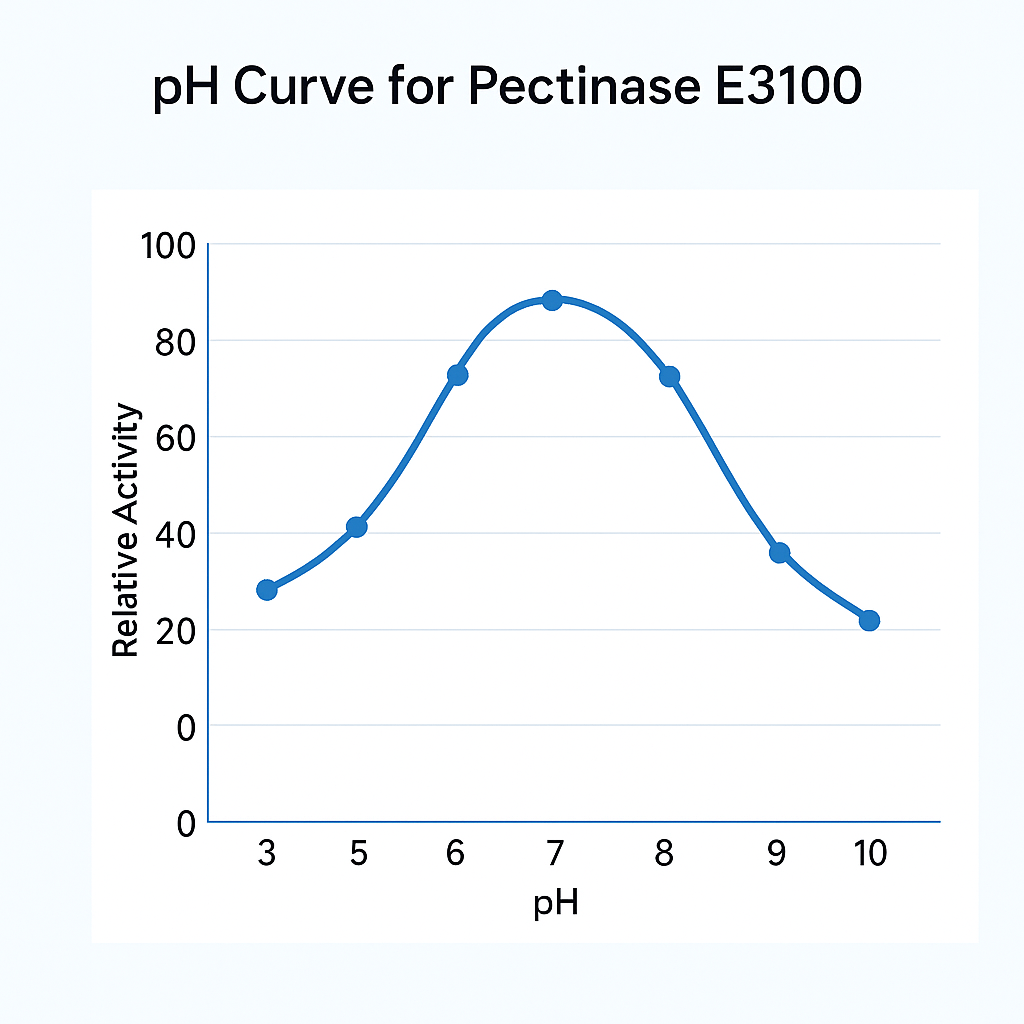

Enzyme Activity Profile

The activity of Neutral Pectinase E3100 is influenced by pH and temperature.

The enzyme shows excellent activity between pH 5.0 – 8.0 and a temperature range of 45°C – 65°C.

Graphs of the relative activity versus pH and temperature are provided below.

(Charts will be provided in downloadable format.)