Food Grade Transglucosidase (α-Glucosidase) Enzyme for Isomaltooligosaccharide (IMO) & Isomaltose Production-100g

Transglucosidase, also known as α-glucosidase, is a food-grade enzyme preparation widely used in hrano, chemical, in biotechnology / medical-related applications that require carbohydrate conversion. This enzyme supports both hydrolysis in transglycosylation reactions, promoting the formation of α-1,6 glycosidic bonds and enabling the production of functional sugars such as isomaltooligosaccharides (IMO) in isomaltose.

In industrial sugar and starch processing, transglucosidase is valued for its ability to reshape carbohydrate profiles beyond simple glucose release. Unlike enzymes that only break down starch into fermentable sugars, transglucosidase can transfer glucose residues to other sugar molecules, forming branched oligosaccharides that contribute to improved stability, a smoother sweetness profile, and enhanced functional sugar content. It is often used to support the manufacture of functional sweeteners, low-sugar syrup systems, and carbohydrate-modified ingredients.

Ključne prednosti

- Supports IMO production by promoting α-1,6 glycosidic bond formation

- Helps generate non-fermentable / low-fermentable oligosaccharides depending on process design

- Improves carbohydrate profiles for functional sweeteners and syrup applications

- Works effectively under mild acidic to neutral conditions

- Fully water-soluble liquid enzyme, easy to dose in batch or continuous processes

Priporočeni odmerek

Recommended addition level: 120–180 U/g (based on substrate dry matter). Dosage may be adjusted depending on solids content, reaction time, and desired oligosaccharide distribution.

Recommended Process Conditions

- Temperature working range: 35–70°C

- pH working range: 3.5–6.5

- Suggested reaction reference conditions: 58–60°C, pH 5.0–5.5, 30 hours (optimize based on your process goals)

Informacije o izdelku

Sestavine: Transglucosidase; carrier/stabilizer: glycerol

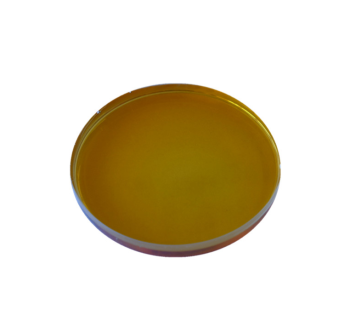

Videz: Svetlo rumena tekočina

Mehanizem delovanja

Transglucosidase (α-glucosidase) participates in carbohydrate conversion by exhibiting both hydrolytic activity in transglycosylation activity. It can hydrolyze α-glucosidic bonds to release glucose and, importantly, it can transfer glucose residues from substrates (such as oligosaccharides) to acceptor molecules, forming new glycosidic linkages. Through this process, glucose residues can be relocated from α-1,4 bonds and reassembled as α-1,6 bonds, resulting in the formation of non-fermentable, low-reducing oligosaccharides such as IMO.

Aplikacije

- Isomaltooligosaccharide (IMO) syrup manufacturing

- Isomaltose and functional carbohydrate conversion

- Sugar and starch deep processing

- Fermentation substrates and carbohydrate modification

- Food, chemical, and biotechnology-related industrial uses

Quality & Typical Specifications

- Gostota: 1.05–1.25 g/mL

- pH (25 °C): 3.0–5.5

- Svinec (Pb): ≤ 5,0 mg/kg

- Total arsenic (as As): ≤ 3,0 mg/kg

- Total plate count: ≤ 50.000 CFU/ml

- Koliformne bakterije: < 30 CFU/mL

- E. coli: < 10 CFU/mL or < 3.0 MPN/mL

- Salmonella (25 mL): Ni zaznano

Skladiščenje in ravnanje

Shranjujte zaprto v hladno in suho okolje. Refrigerated storage is recommended to maximize activity retention. Avoid prolonged exposure to high temperatures and direct sunlight. Keep container closed when not in use to reduce contamination risks.

Pakiranje

0.1 kg bottle (supplied in an industrial-grade plain bottle). Please note that the product image is for illustration purposes. Actual packaging may differ.

Opombe

Process performance depends on substrate composition, reaction setup, and production targets. For best results, we recommend conducting a pilot trial to determine optimal dosage and reaction time for your specific application.