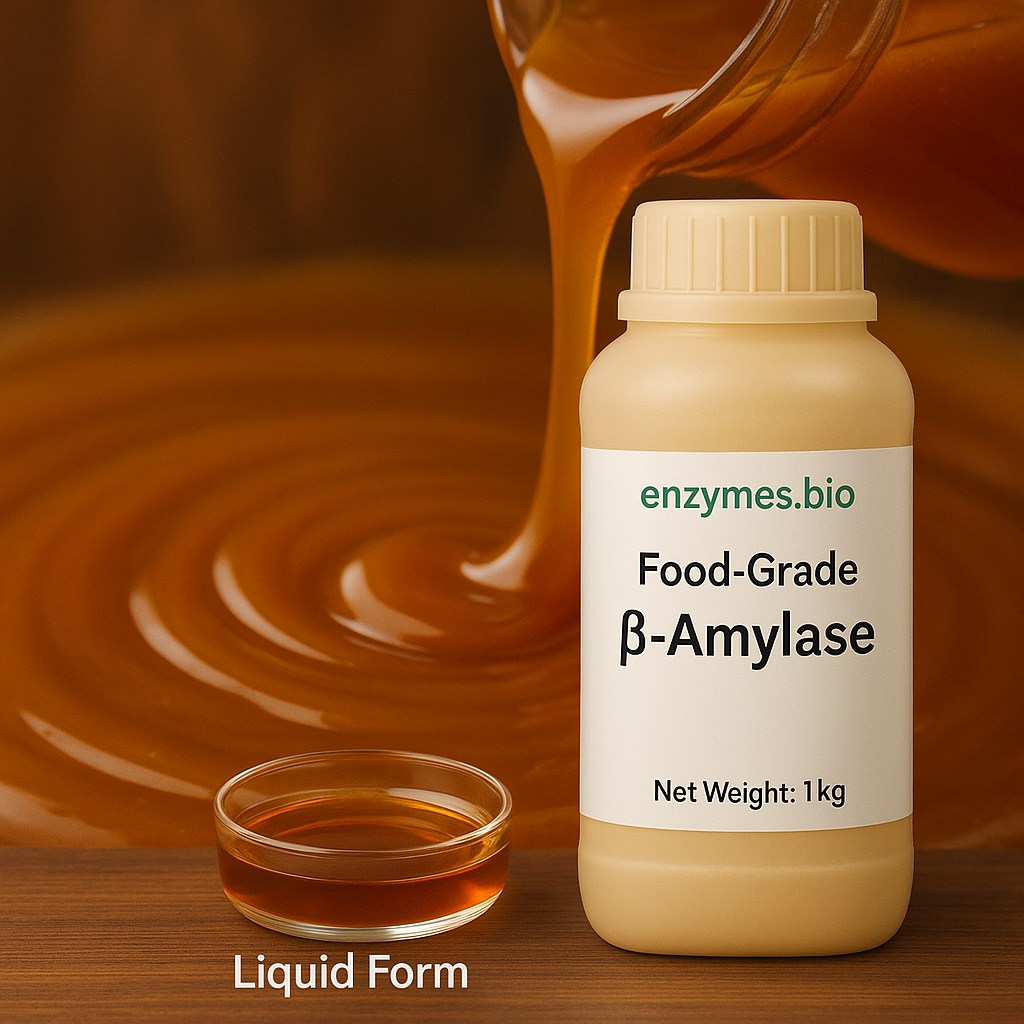

Food-Grade β-Amylase – High-Activity Liquid Enzyme for Maltose Production

Food-grade β-amylase (700,000 U/mL) is a highly efficient liquid enzyme designed for starch-to-maltose conversion in a wide range of food processing applications. As an exo-acting enzyme, β-amylase selectively hydrolyzes the α-1,4 glycosidic bonds at the non-reducing ends of starch molecules, releasing maltose units with exceptional conversion efficiency.

This product is formulated as a clear, light brown liquid with high stability, excellent solubility, and strong performance within typical food manufacturing environments. Its activity profile enables manufacturers to achieve controlled hydrolysis, enhanced sweetness, improved viscosity profiles, and optimized fermentation characteristics in various starch-based formulations.

Key Features

- High Enzyme Activity: 700,000 U/mL for powerful starch degradation.

- Food-Grade Quality: Suitable for direct use in food and beverage processing.

- Consistent Liquid Form: Easy to dose, blend, pump, and incorporate into automated systems.

- Stable Performance: Robust activity across a wide temperature and pH range.

- Clean Reaction Profile: Produces maltose with minimal by-products.

Typical Applications

This β-amylase is widely used in starch-based food manufacturing where maltose generation,

sweetness enhancement, or controlled viscosity reduction is required. Common applications include:

- Maltose syrup production and starch hydrolysis lines

- Honey-like syrup, pancake syrup, and dessert sauce formulation

- Cereal and grain-based beverage processing

- Baked goods, confectionery, and snack coating systems

- Fermentation processes requiring maltose enrichment

Functional Benefits

- High Maltose Yield: Efficient release of maltose from various starch sources.

- Improved Flavor & Sweetness: Enhances sweetness profile without off-flavors.

- Process Optimization: Helps achieve predictable viscosity and texture in syrups.

- Excellent Compatibility: Works well with corn, wheat, cassava, and other starches.

- Flexible Integration: Can be used alone or combined with other amylases for advanced hydrolysis strategies.

Recommended Operating Conditions

- Temperature Range: 40–65°C

- Optimal pH: 3.5–6.0

- Suggested Dosage: 0.1–1.5 kg per ton of starch material (adjust according to process requirements)

Actual dosage will vary depending on the substrate, target maltose level, reaction time, and process configuration. Preliminary small-scale testing is recommended to identify the optimal usage level.

Product Appearance

Light brown liquid with characteristic enzyme odor.

Packaging & Shelf Life

- Packaging: 1 kg bottle (supplied in an industrial-grade plain bottle). Please note that the product image is for illustration purposes. Actual packaging may differ.

- Shelf Life: 12 months when stored sealed in a cool, dry environment away from direct sunlight

Storage Recommendations

Store the product in a tightly closed container under cool and dry conditions.

Avoid prolonged exposure to high temperatures.

Keep away from oxidizing agents to maintain maximum enzyme activity.

Safety & Handling

This enzyme is non-toxic and safe for use in food processing when handled appropriately.

As with all protein-based materials, avoid inhalation of aerosols and contact with eyes.

Use standard protective equipment during handling.